Our Capabilities

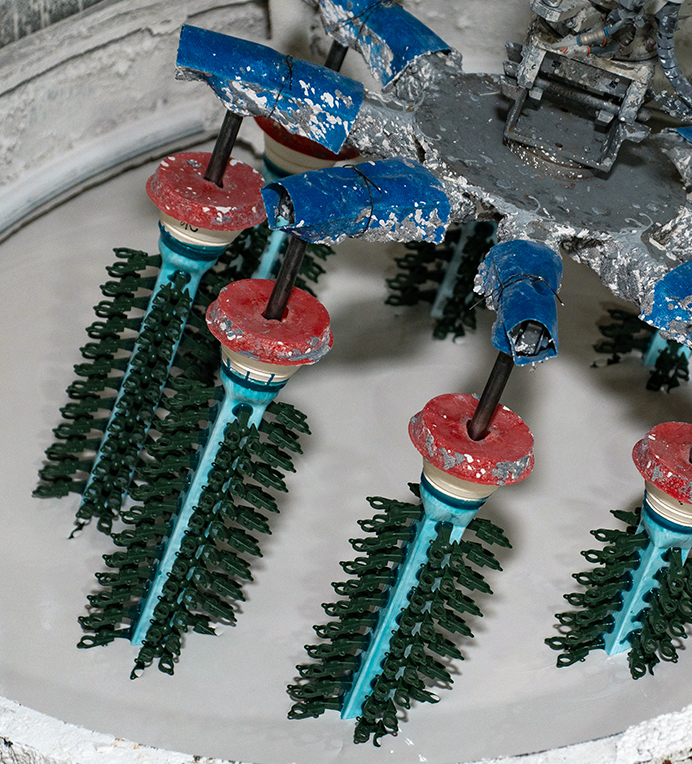

Our in-house engineering and tool-building team manage and deliver complex investment casting projects from start to finish and within a wide range of industries – offering the shortest lead times in the industry.

Experience the Franklin Difference

Our end-to-end capability, prompt technical and customer support, and dedicated team with a “can do” attitude are a few of the reasons our customers keep recommending Franklin. In addition, here are a few reasons that make us stand out versus the competition:

- Ability to pour more than 120 alloys

- In-house engineering and tooling manufacturing

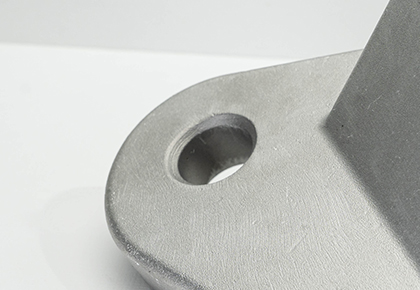

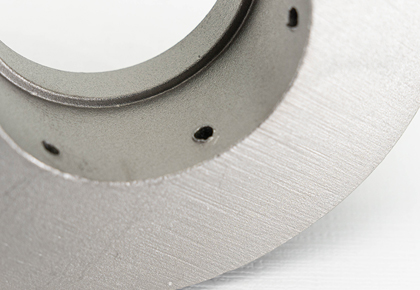

- Ability to deliver fully finished components/kits

- Shorter lead times

- Made in the USA

- Responsive and flexible technical support team

- Nearly 40 years of experience

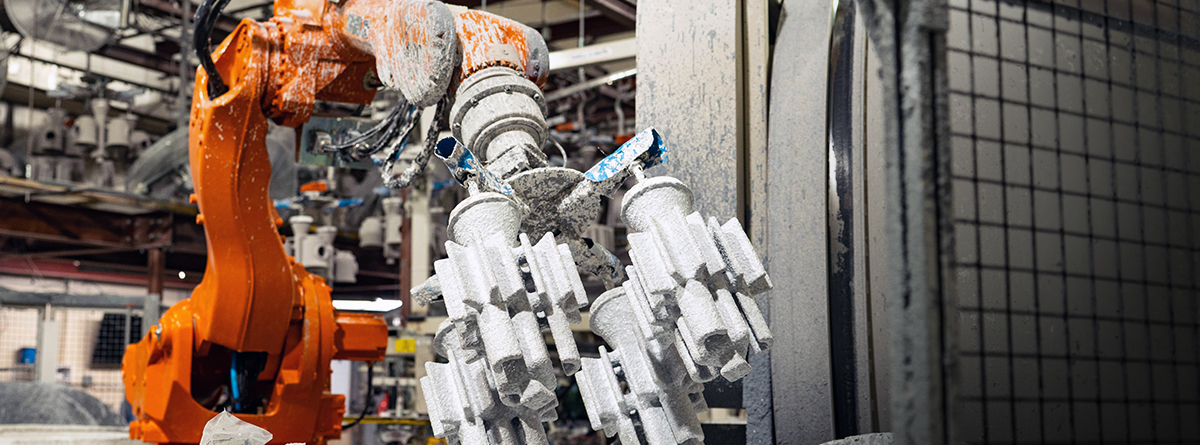

- Robotic, automated foundry for consistent quality

Industries We Serve

For nearly four decades, Franklin Precision Castings has served as a trusted partner providing high-quality investment castings to customers in a variety of industries, from glass, food, and metal processing to pumps and valves and beyond.

Alloys We Pour

We pour over 120 alloys in our U.S.-based facility, including standard and custom stainless steel, nickel, cobalt, brass, bronze, and Ni-Hard alloys to suit the requirements of complex cast subassemblies or assemblies.