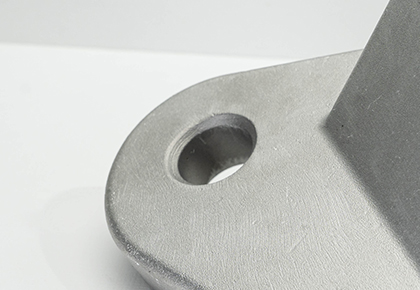

Castings Designed for the Harshest Conditions

At Franklin, we understand the critical importance of leveraging strong metals and precision engineering for components in the oil, gas, and mining industries, many of which are subjected to harsh conditions – whether deep underground or high in the sky. Our expertise in creating high-strength and corrosion-resistant investment castings ensures your parts are up to the task when it comes time to withstand the extreme conditions encountered in oil, gas, and mining operations.

Why Franklin for the Oil, Gas, & Mining Industries?

Franklin specializes in the manufacture of high-strength and corrosion-resistant parts ideal for withstanding the harsh conditions encountered in oil, gas, and mining operations. With decades of experience, our team of experts brings the knowledge and expertise needed to understand and address the specific challenges and requirements of oil, gas, and mining sectors.

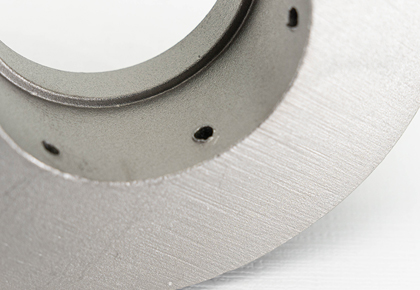

Alloys We Pour

We pour over 120 alloys in our U.S.-based facility, including standard and custom stainless steel, nickel, cobalt, brass, bronze, and Ni-Hard alloys to suit the requirements of complex cast subassemblies or assemblies.