Your Home for Fully Machined Castings

Our onsite 5,000-square-foot CNC machine shop allows us to offer fully machined castings, eliminating the expense and delays associated with outsourcing to third-party vendors. Franklin offers a comprehensive solution from a single, U.S.-based source.

CNC Machining

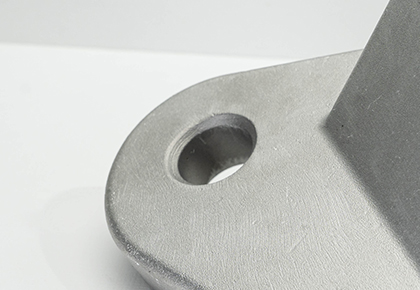

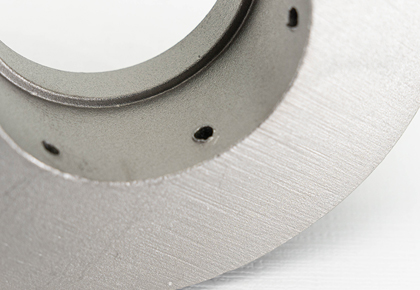

CNC (computer numerical control) machining is a versatile manufacturing process that utilizes computer-controlled machinery to precisely shape and finish metal components. Within the context of investment casting production, CNC machining plays a critical role in refining and finishing castings to meet exact specifications.

Franklin Precision Castings continues to invest in the latest CNC machining technologies. Franklin can provide finished, ready-to-assemble parts from a single source. Finished components range from industries such as food processing, oil and gas, pumps and valves, and marine.

Components are finished to tolerances up to 0.010mm on the most modern machining centers which are fully equipped with in-line measure probes.

Machining Equipment

Why Franklin for CNC Machining?

Franklin provides CNC machining in-house following its investment casting production, outputting high-quality, custom components.

Alloys We Pour

We pour over 120 alloys in our U.S.-based facility, including standard and custom stainless steel, nickel, cobalt, brass, bronze, and Ni-Hard alloys to suit the requirements of complex cast subassemblies or assemblies.