Accelerate Speed to Market

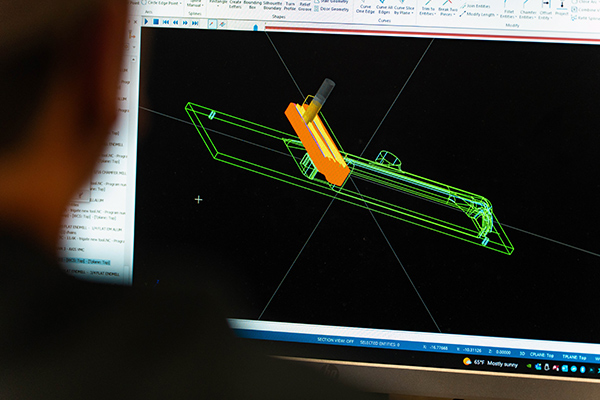

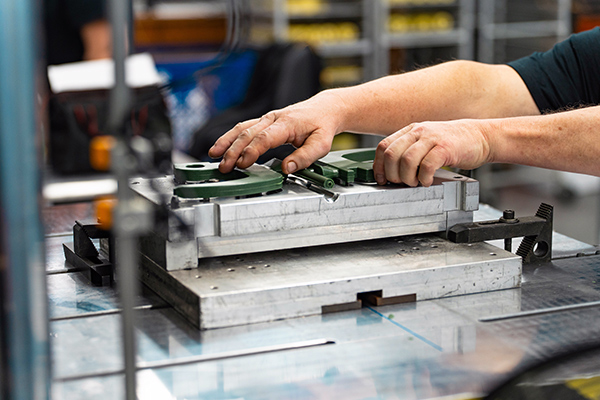

Since 1992, Franklin has operated our own 5,000-square-foot in-house tool-making facility. This has enabled us to expedite casting deliveries, develop new products, and save our customers time and costs. Led by our skilled engineers, we are able to quickly design and manufacture all necessary tooling in-house.

Advantages of In-House Tooling

- Efficient delivery and reduced lead-times

- Increased customization and flexibility

- Direct oversight and control over the entire design and manufacturing process

- Ability to tailor solutions to meet specific project requirements

- Improved quality control and production consistency

- Significant cost and time savings compared to third-party outsourcing

Why Franklin for In-House Tooling?

Our in-house tooling process gives us greater control, customization, and speed over outsourcing alternatives. Additionally, controlling all aspects of the tool build process enables Franklin to quickly adapt to design requests throughout the process.

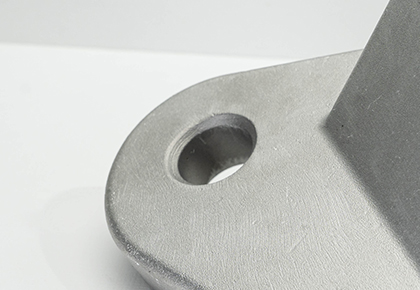

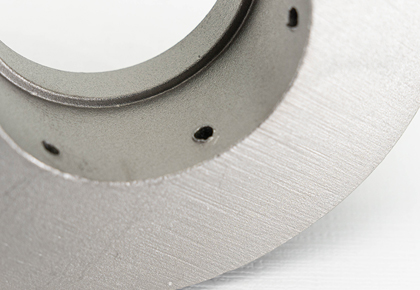

Alloys We Pour

We pour over 120 alloys in our U.S.-based facility, including standard and custom stainless steel, nickel, cobalt, brass, bronze, and Ni-Hard alloys to suit the requirements of complex cast subassemblies or assemblies.