Your Go-To Partner for High-quality Finishing

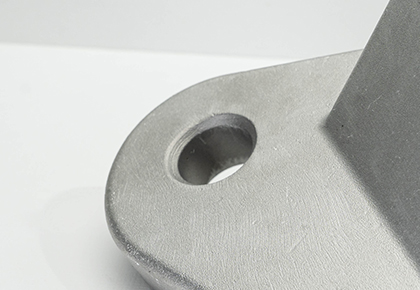

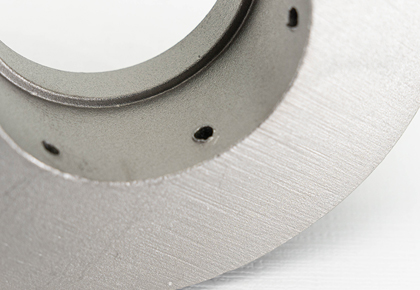

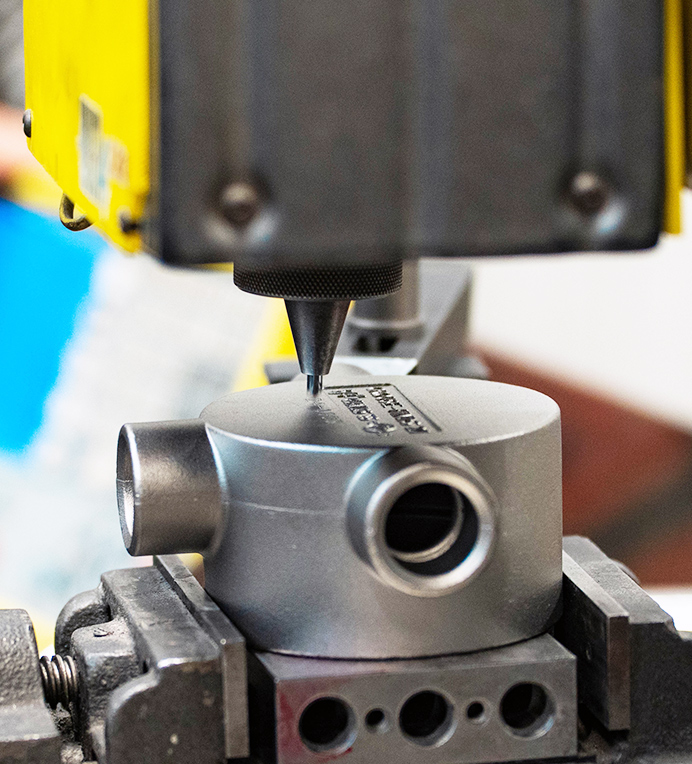

Our comprehensive range of secondary processes, including machining, laser etching, heat treating, electropolishing, and more, ensures your components receive the finishing touches they need while upholding our standard of quality. We provide a one-stop solution to meet all your finishing requirements.

Advantages of Secondary Processes

- Improved durability, strength, and corrosion resistance for cast parts

- Smoother surface finish and a more uniform texture

- Tighter tolerances for critical dimensions

- Improved customization

- Ability to brand parts with logos, part numbers, and more

- Improved defect detection, traceability, and quality assurance

- Flexibility in material selection and surface treatment options

Why Franklin for Secondary Processes?

By offering secondary processes alongside our investment casting services, Franklin provides a streamlined process that minimizes lead times, reduces costs, and simplifies project management for our customers.

Alloys We Pour

We pour over 120 alloys in our U.S.-based facility, including standard and custom stainless steel, nickel, cobalt, brass, bronze, and Ni-Hard alloys to suit the requirements of complex cast subassemblies or assemblies.