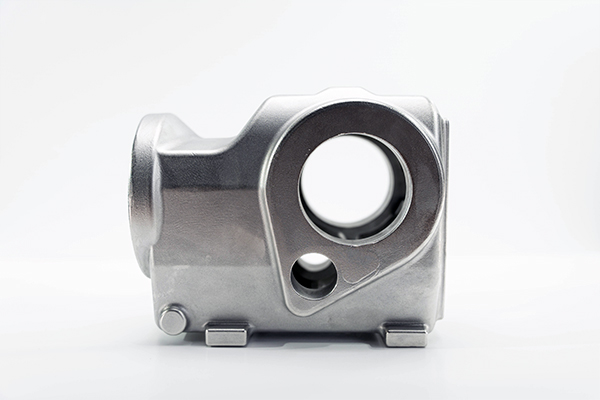

Precision-Engineered Castings for Food Processing Components

Franklin offers tailored investment casting solutions for businesses in the food processing sector, designed to improve the efficiency, hygiene, and performance of many different types of food processing equipment. From canning and mixing equipment to components made for bread and meat manufacturing, our versatile, full-service offering meets the needs of a wide variety of food processing applications. Our expert team is here to provide design assistance and personalized support to optimize everything from project execution to component performance.

Why Franklin for the Food Processing Industry?

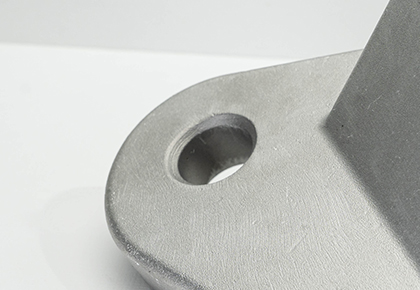

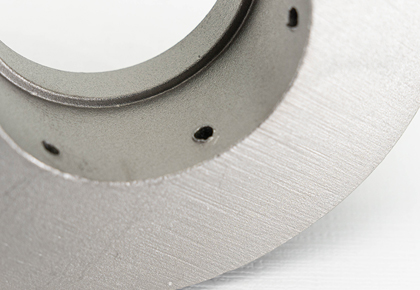

Franklin’s investment castings are engineered for durability and longevity, capable of withstanding the rigorous demands of food processing environments while reducing downtime and maintenance costs for operations like yours. Throughout our process, we utilize materials that comply with food safety standards to help ensure your parts are hygienic and safe for contact with food products.

Alloys We Pour

We pour over 120 alloys in our U.S.-based facility, including standard and custom stainless steel, nickel, cobalt, brass, bronze, and Ni-Hard alloys to suit the requirements of complex cast subassemblies or assemblies.