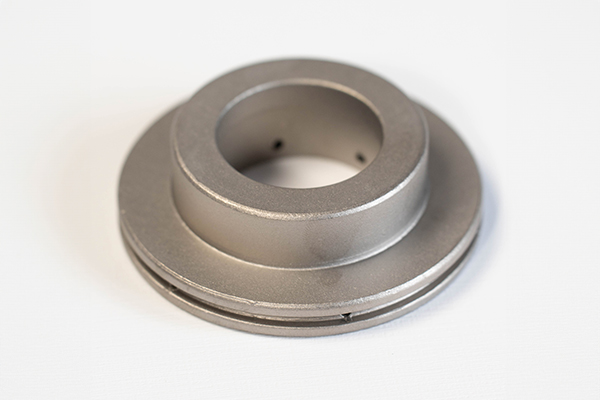

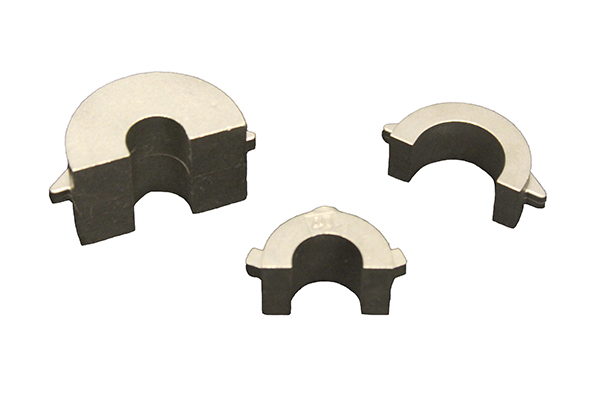

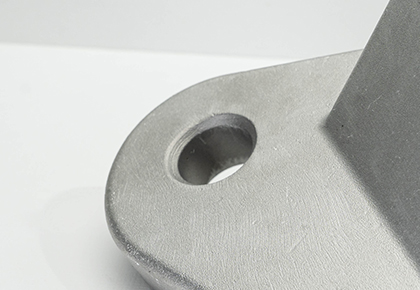

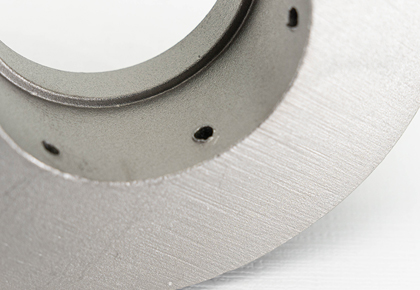

Guide Rings, Plungers, Baffles, Inserts, and More

Franklin is a world leader in the manufacture of investment castings for the glass industry. Cast parts for glass include guide rings, plungers, baffles, neck ring inserts, thimbles, top plates, and more. Our customers in the glass industry continue to rely on us to deliver investment cast parts on tight timelines – which we can achieve due largely to our in-house tooling making capabilities and vast tooling inventory.

We pour a wide range of alloys for the glass industry, including nickel, brass and bronze, cobalt, and stainless steel – right here at our U.S.-based facility. We serve as a dedicated and experienced partner for our customers.

Why Franklin for the Glass Industry?

The Franklin team has decades of experience manufacturing investment castings for the glass industry. In fact, the glass industry is where we got our start in 1985 – and so our operations are rooted in and designed around speed, quality, and consistency, every time.

Alloys We Pour

We pour over 120 alloys in our U.S.-based facility, including standard and custom stainless steel, nickel, cobalt, brass, bronze, and Ni-Hard alloys to suit the requirements of complex cast subassemblies or assemblies.