Cost Effectively Reduce Machining Cycles

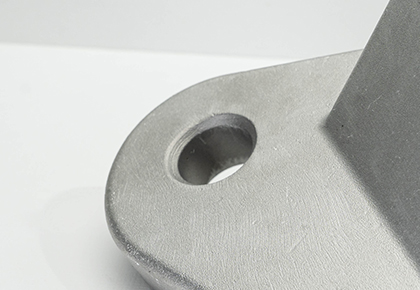

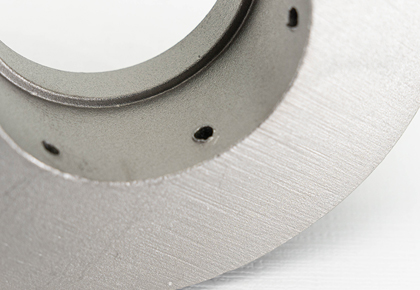

As a machine shop owner, you understand the importance of using high-quality metal forms to produce precise components for a wide range of applications. Franklin offers an alternative to traditional metal forms by providing investment castings that offer versatility and precision. Investment castings can replace bar stock, forgings, welded fabrications, sand castings and more. Investment castings can offer machine shop owners a cost-effective solution by reducing machining cycles.

Why Franklin for Your Machine Shop?

Franklin works closely with machine shop owners to understand their specific requirements and preferences, often tailoring our solutions in a way that will optimize component performance, reliability, and cost-effectiveness. Our expert team also specializes in collaborating with customers to convert many machined, welded fabrication, forging, assembly, or sand casting to investment casting, unlocking new possibilities for your business and overall production.

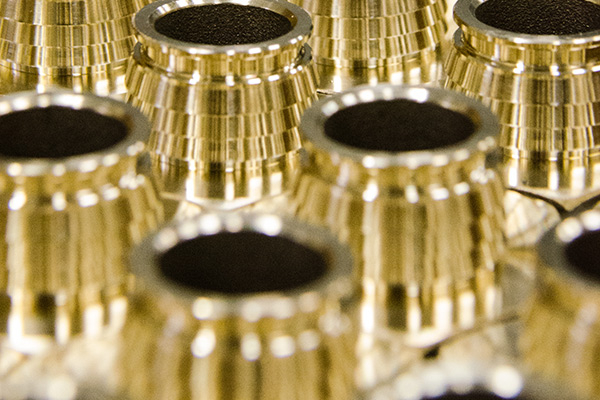

Alloys We Pour

We pour over 120 alloys in our U.S.-based facility, including standard and custom stainless steel, nickel, cobalt, brass, bronze, and Ni-Hard alloys to suit the requirements of complex cast subassemblies or assemblies.