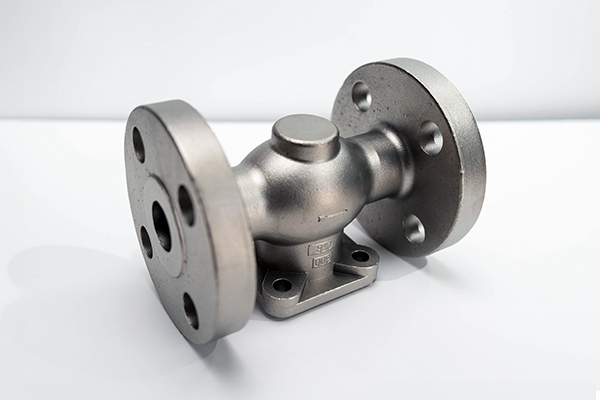

Reliable, High-precision Castings for Pumps and Valves

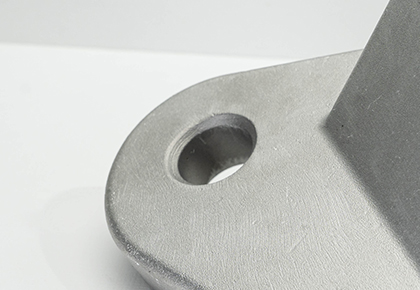

Led by our decades of expertise in investment casting, we provide tailored solutions to meet the unique needs of the pumps and valves industry. From fittings and pump bodies to valve bodies, stems, brackets, and handles, we take steps to ensure our process allows for intricate geometries and that it produces components that meet even the strictest tolerances and specifications.

Why Franklin for the Pumps & Valves Industry?

At Franklin, we pride ourselves on being a responsive and flexible partner, dedicated to providing personalized support and expertise to our customers in the pumps and valves industry.

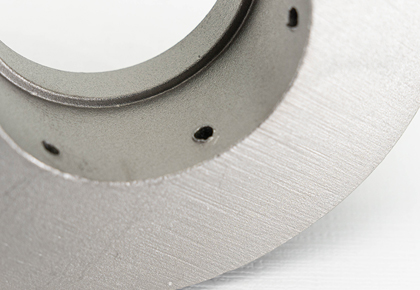

Alloys We Pour

We pour over 120 alloys in our U.S.-based facility, including standard and custom stainless steel, nickel, cobalt, brass, bronze, and Ni-Hard alloys to suit the requirements of complex cast subassemblies or assemblies.